How to Create an Efficient Cargo Loading Plan: A Step-by-Step Guide

If you work in logistics and care about costs as well as your employees’ sanity, you probably already know that load and capacity planning is a big topic that shouldn’t be ignored. Why? Because without an optimized load plan, you won’t make the most of your cargo space, and your warehouse staff will spend significantly more time than necessary loading cargo.

Source: www.canva.com

What steps go into creating a load plan?

- Assess cargo specifications: Identify the dimensions, the weight, and the type of cargo to ensure proper handling and placement.

- Consider specific cargo requirements: Take into account any special requirements such as orientation, fragility, or the need for extra securing methods to prevent movement during transport.

- Optimize space utilization: Arrange the cargo efficiently to maximize available space and minimize wasted capacity.

- Ensure proper weight distribution: Balance the load evenly to prevent instability and comply with weight regulations.

- Finalize and review the plan: Double-check the load arrangement and make necessary adjustments before execution.

Now, let’s break down each step in detail.

Note: It’s up to you which tools you use to create the cargo loading plan. In this article, we will provide instructions on how to process each step manually or by using the EasyCargo load planning software.

Source: www.canva.com

Step 1: Assess Cargo and Transport Specifications

The first step is to gather the essential information you need to move forward with the creation of a cargo loading plan.

a. Know Your Cargo Dimensions

To create an effective load plan, you need to know the dimensions (length, width, height) and the weight of the cargo. You likely have this information in your internal systems. If you don’t, it may be necessary to take a tape measure to determine the dimensions.

Manually

First, create a table in Excel with columns for:

- cargo ID/name

- length

- width

- height

- weight

Next, measure each piece of cargo (or consult your internal systems for this data) and input the measurements into the Excel table. If the cargo is irregularly shaped, try to break it down into manageable dimensions or use the largest measurements to account for its size. Finally, double-check the accuracy of the measurements to ensure the data is correct.

With the EasyCargo Load Planning Software

With the EasyCargo software, you can manually enter the individual dimensions or import the items from Excel. The main advantage is that you can save the individual items to the cargo items database, and next time, you can select them without having to re-enter their details.

b. Choose Your Cargo

Once you have the dimensions and weight of all items, the next step is to choose the best cargo space for your cargo. In addition to the cargo dimensions, it’s important to consider the interior dimensions of the cargo space, including the length, width, and height available for loading. The basic rule is that the cargo space should be large enough to accommodate your items while leaving enough room for proper weight distribution and securing.

Choosing the right cargo space is not easy because there are many different types of cargo spaces, and each is suitable for different types of goods. If you’re unsure about which cargo space to use, take a look at our article: Different Types of Shipping Containers, Trailers, Trucks, and More: Choose the Best Cargo Space for You, where you’ll find clear tables of available spaces and their suitable uses.

Manually

Enter the interior dimensions of the cargo space into your Excel table next to the dimensions of the cargo to determine which cargo space is best suited for your shipment. To do this, sum up the dimensions of all items and compare them with the dimensions of the cargo space.

Tip: Are you unsure about how to calculate truckload capacity? Don’t worry, we’ve written an entire article on this topic.

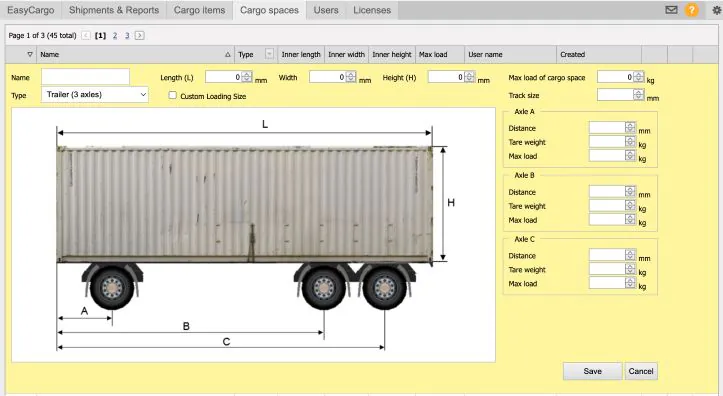

With the EasyCargo Load Planning Software

In the EasyCargo application, you can choose from 45 different cargo spaces. Therefore, everyone can find the most suitable one for their specific load. This saves you a ton of time since you don’t have to enter the dimensions for each space manually—just click the star next to the cargo space to mark it as a favorite so you can access it under the EasyCargo tab and you’re ready to go. Do you have a unique cargo space? If so, you can easily create your own custom cargo space.

Case study: GLT Logistics had trouble visualizing cargo placement in trucks, making communication with customers difficult and slowing down space calculations. After using EasyCargo, the need for manual planning was reduced, speeding up the process and improving accuracy. Read the full case study here.

Step 2: Consider Specific Cargo Requirements

Fitting your cargo into the space is just the first step. You also need to consider special cargo requirements such as the need for certain items to remain in a specific orientation, the fragility of the cargo, or the need for additional securing methods to prevent movement during transport.

Manually

At this point, you’ll likely realize that an Excel spreadsheet is not all that powerful when it comes to shipment planning. Nevertheless, it’s important to record all of the specific requirements for each item. Whether it’s orientation, fragility, or special securing needs, making a note of these details will help ensure the proper handling of each piece of cargo.

With the EasyCargo Load Planning Software

EasyCargo allows you to select the appropriate specific requirements for each item and it is really easy to do so. Simply click on the selected item and choose any of the following restrictions:

- Do not tilt this cargo item.

- Do not stack on this cargo item.

- Do not rotate this cargo item.

Step 3: Optimize Space Usage

Now that you’ve assessed your cargo and considered specific handling requirements, the next step is to optimize the use of available cargo space. Here is how to do it:

Manually

Here, you’ll either need a lot of imagination or a lot of time (or both). Based on the dimensions and weight, start thinking about the best way to arrange the cargo in the cargo space. You can draw the cargo space and cargo in reduced size on paper or create a table in Excel with different arrangement options.

Choose the best option that will comply with all of the special requirements while maximizing space utilization.

With the EasyCargo Load Planning Software

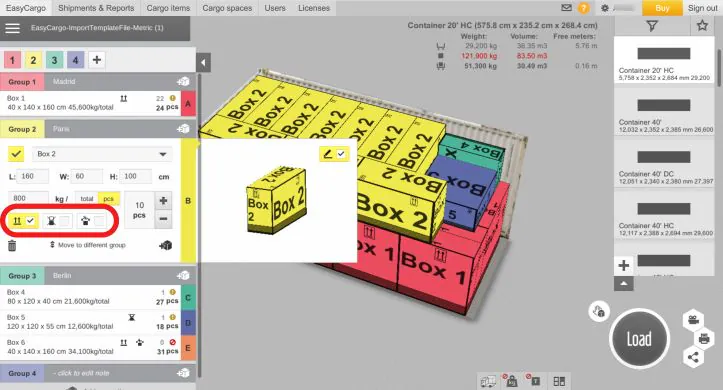

You might think that planning a cargo load manually is no different from using EasyCargo. But think again. In the EasyCargo app, all of the necessary data is already entered, and you just need to click the ”Load” button, and it’s done.

The software automatically generates an optimized load plan in just a few seconds. It arranges the cargo in the best way possible to maximize space usage and ensures that the arrangement complies with specific requirements.

Tip: If the load plan created for you doesn’t 100% meet your expectations, you can easily adjust it manually.

Source: www.canva.com

Step 4: Ensure Proper Weight Distribution

Proper weight distribution is one of the most important factors for safe transportation. If the cargo is poorly distributed, it can lead to overloading one or more of the axles. This not only results in increased vehicle wear but also reduces its stability and maneuverability. In addition to increased vehicle wear and decreased stability, most regions have strict regulations when it comes to how commercial vehicles are loaded. Improper loading of trucks can result in hefty fines and also imprisonment in some areas. That is why it’s crucial to ensure that the load is evenly balanced across all axles.

Manually

Calculate the total weight and evenly distribute it across the available space in the cargo area to prevent the overloading of one or more of the axles. Then, check your load plan to ensure it reflects proper weight distribution and adjust the plan if necessary.

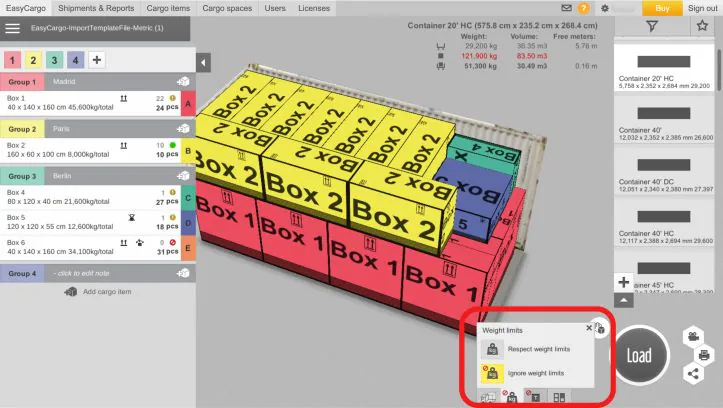

With the EasyCargo Load Planning Software

In the application, you can set whether you’ll respect the weight limits of your cargo space or not, and you can even check the load on each axle. This means that even before the actual loading process, you can see if the weight distribution is balanced or if the plan needs to be adjusted. Yes, you’re right —in EasyCargo, it’s much easier.

Tip: Learn how to work with the weight of a shipment to avoid overloading your vehicle.

Step 5: Finalize and Review the Load Plan

Once you have optimized the space, ensured proper weight distribution, and considered all of the specific requirements, it’s time to finalize your load plan and review it for any potential issues.

Manually

When reviewing manually, you will need to check all of the data and calculations once more. If you find any discrepancies, you’ll have to make adjustments and update the plan. Once you have reviewed the cargo loading plan, you can share it with other employees.

With the EasyCargo Load Planning Software

With EasyCargo, once the plan is finalized, you can review it. The plan is also easily adjustable. Therefore, if any adjustments are necessary, you can make them with just a few clicks. After that, you can export it into a PDF file, share it with your team via a link, or print it with detailed instructions.

As you can see, creating a load plan is quite a challenge. But not when you use EasyCargo. In addition to saving a few brain cells, it also brings you several key benefits:

- Time savings: You can quickly generate a cargo loading plan in just a few clicks, eliminating the time-consuming process of manual calculations and trial-and-error arrangements.

- Maximized space utilization: The software automatically calculates the best way to arrange your cargo, ensuring that every inch of the cargo space is used efficiently. This helps reduce unused space, meaning fewer trips and more cargo sent per shipment.

- Cost reduction: By optimizing space and reducing wasted cargo capacity, EasyCargo helps minimize transportation costs. You can fit more cargo into each shipment, reduce the need for additional transport, and ultimately lower your overall expenses. Additionally, the software significantly reduces the time your employees spend creating load plans, allowing them to focus on more important tasks.

- Lower CO2 emissions: More efficient space usage means fewer trucks, fewer trips, and lower fuel consumption. This directly contributes to reducing your company’s carbon footprint, supporting sustainable logistics practices.

Are you ready to take advantage of all these benefits in your company? Try the EasyCargo load planning software for free for 10 days.

Source: www.canva.com

Frequently Asked Questions

1. What is a cargo loading plan?

A cargo loading plan is a detailed strategy for arranging and loading goods into a cargo space, such as a truck, container, or trailer. And that’s not all. A good cargo loading plan ensures that the goods are loaded in a way that maximizes space, ensures proper weight distribution, and meets any specific cargo requirements.

It helps ensure that all goods are loaded efficiently and securely for transportation, reducing risks during transit and optimizing overall logistics.

2. How do you calculate the cargo load?

To calculate the cargo load, you need to sum the weight of all the items being transported. This includes both the actual cargo and any packaging, securing materials, or additional items. Once you know the total weight, you can determine the most appropriate cargo space in which all of the cargo comfortably fits, and at the same time, you won’t be transporting wasted space.

3. How do you make a container load plan?

The simple process for creating a load plan is as follows:

- assess cargo specifications,

- consider specific cargo requirements,

- optimize space usage,

- ensure proper weight distribution,

- and finalize and review the plan.

4. What is the basic rule when loading a container?

The basic rule when loading a container is to maximize the use of available space while ensuring safety and stability. This means distributing the weight evenly across the container as well as securing the cargo properly to prevent shifting during transport.

It’s also essential to consider any special requirements for fragile or sensitive items to avoid damage during transit.

Try the EasyCargo load planning software today to maximize space utilization, reduce time, and save money. Are you not sure if EasyCargo is the right choice for you? Try the software for free for 10 days and see for yourself!