How to stack a pallet effectively?

Interested in learning more about how to stack pallets efficiently and effectively? If you are involved in freight forwarding, logistics, or optimization, then don’t miss our series of four articles on this topic. In this series, we will talk about the different steps to stack pallets, and pallet stacking patterns, make a comparison between column stacking vs. interlocking stacking, and finally answer the question: How do you stack mixed pallet boxes?

Don’t miss this must-read series for anyone involved in freight optimization and logistics!

Efficiently stacking a pallet is an important skill for anyone working in logistics or freight forwarding. A well-stacked pallet not only ensures the safety of the load during transport but also maximizes the available space and reduces shipping costs. In this blog, we will show you the basic steps to stack a pallet correctly.

Properly shipping goods to your customers involves many variables to consider, such as which corrugated box is best for orders or how to ship your small business’ goods at the best price. And when working in a distribution center, knowing how to stack a pallet to make sure the contents are not damaged is the top priority in shipping.

It’s worth noting that proper stacking is what keeps your employees safe from boxes tipping over and also helps optimize transportation costs so you make money for your efforts.

Source: https://www.nikecolombiana.com/wp-content/uploads/2021/08/montacargas-nike-6-1280×720.jpg

The following describes the best way to stack a pallet:

1. Pallet preparation

Before starting to stack the load on the pallet, it is important to make sure that the pallet is clean and in good condition. Check that there are no broken or damaged parts and that all boards are securely fastened to the frame. Also, make sure the pallet is the right size for the load to be transported.

They provide a stable and convenient platform for loading and unloading items, making it easier to move large quantities of goods efficiently.

2. Plan your pallet stacking pattern

The actual stacking pattern will vary based on your specific items and requirements. Always consider safety, weight distribution, and stability when planning your pallet stacking pattern

Note what type of items are to be transported and what they contain.

- If they are all different sizes and weights, or all the boxes are the same size but very heavy, it is best to use an interlocking pattern.

- If the boxes are of the same size and low density, then a columnar stacking pattern is best.

We will explain in the third article in more detail about the terms interlocking pattern and column stacking.

3. Place the heaviest boxes first

When stacking a pallet, it is important to place the heaviest products on the bottom. This helps distribute the weight evenly and prevents the load from tipping over or being damaged during transport. Generally, heavier products are placed in the center of the pallet, leaving a margin of space at the edges for lighter products.

4. Arrange the products in an orderly manner

As the load is stacked, it is important to arrange the products in an orderly and uniform manner. Products should be aligned and well packed to minimize the space they take up. If products of different sizes are to be stacked, it is important to ensure that the larger products are at the bottom and the smaller ones are at the top.

5. Align the boxes close to the edge

The recommended practice for pallet loading is to center the boxes on the pallet, ensuring even weight distribution for stability. It’s crucial to maintain a sufficient margin of empty space around the edges to facilitate secure strapping or stretch wrapping for load stability during transit. If considering placing boxes close to the edge, a thorough assessment of risks, including weight distribution, size, and shape of the boxes must be conducted to prevent pallet destabilization and potential hazards. However, in some specific cases, it may be beneficial for boxes to overhang.

6. Secure cargo with strapping or plastic wrap

Once the load has been stacked on the pallet, it is important to secure it to prevent it from moving or shifting during transport. Strapping or plastic wrap are excellent options for securing the load. Wrap the pallet with strapping or plastic wrap, making sure the load is secure and will not move.

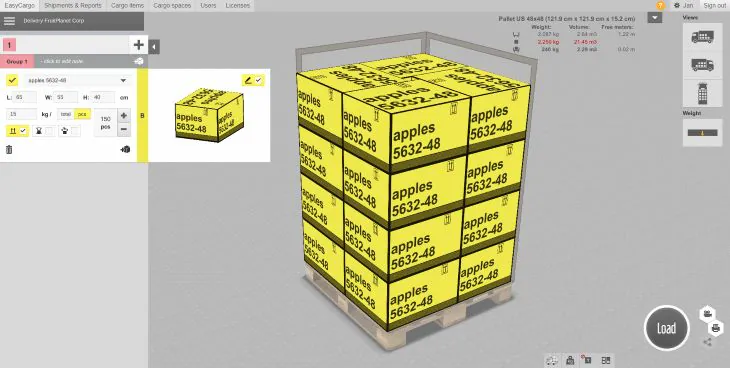

One of the actions performed by EasyCargo, is the search for the use of free space inside the pallets that are often not optimized. EasyCargo generates a loading plan as optimal as possible and thus contributes to loading the pallet in a safe and optimal way. Learn more about how you can benefit from this software by trying it for free.

In conclusion, following these steps will help your cargo to be fully optimized and moved in a safe way.

Now that we have covered the steps for proper pallet stacking. In our next article, we will talk about the different pallet stacking patterns.

Don’t miss the second article in our four-part series on pallet loading!