Stretch by Boston Dynamics and Other Robotic Technologies

You can continue to move all of the goods in your warehouse and cargo spaces manually by hiring many workers to handle the tough tasks. Or, you can embrace the wave of automation and use robotic technologies that will do the heavy lifting and repetitive tasks for you.

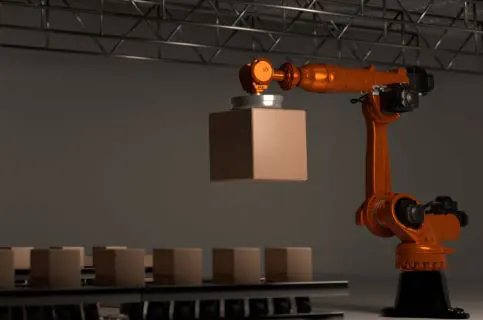

Source: www.canva.com

Read about the new robotic technology from Boston Dynamics that is completely transforming warehousing operations, as well as other technologies that are automating warehouse processes.

Boston Dynamics and Its Technology Called Stretch

Boston Dynamics is an American engineering and robotics design company that develops robotic technology to address the most challenging automation tasks and redefine what is possible for robots to achieve.

One of the robotic process automation technologies developed by this company is Stretch—a versatile mobile platform designed to efficiently handle warehouse operations. Stretch is a giant robotic arm technology that handles the toughest warehouse tasks quickly and efficiently.

What tasks does Stretch handle in the warehouse?

Stretch is currently focused on tasks such as unloading trailers and shipping containers. In the future, Stretch is expected to take on even more tasks in the warehouse, such as:

- mobile palletizing (robotic systems handle and arrange products on pallets without the need for a fixed infrastructure)

- order picking

How does Stretch work?

No more heavy lifting or repetitive boring tasks for you to do. What else can Stretch do?

- Stretch is capable of handling cases that weigh up to 22.7 kilograms (50 pounds).

- It is capable of recognizing and handling different kinds of packaging.

- Thanks to its long battery life, it unloads continuously through two shifts, at any time of day or night, without fatigue or slowdown.

- Picks up multiple cases in one grasp and places them one at a time on the conveyor.

- Keeps the flow of goods moving, even during the holidays.

- Makes all of its decisions in real time with no pre-programming needed.

Moreover, to start using Stretch in your warehouse, you don’t need to change the entire warehouse infrastructure. Thanks to the simple installation and setup process, Stretch is ready to get to work within a few days. Imagine leaving the heavy lifting and unloading of bulky packages entirely to Stretch from now on.

Source: www.canva.com

Stretch is already being used by many companies, including DHL, one of the top logistics companies. This is how Collin Jacobs, Engineer in DHL Supply Chain, evaluated the use of Stretch: “There’s less falls, less drops, and it also allows us consistency. So whenever we have a large and we get a truck that comes in late, we know that because of Stretch, we have that consistent unload throughput rate and it allows us to get those units into our operation as quickly as possible” (Jacobs, cited in bostondynamics.com).

Tip: Did you know that just like Stretch, EasyCargo is also used by many companies, including renowned businesses such as FedEx, John Deere, KTM, Fagor, and Caterpillar? Read specific use cases and discover the benefits that EasyCargo has brought to these companies.

Frequently Asked Questions

1. How much does Boston Dynamics Stretch cost?

Boston Dynamics has not publicly disclosed the exact price of Stretch on its official website. However, some sources indicate that the price is estimated to range between $300,000 and $500,000 per unit.

2. What is the battery life of the Boston Dynamics Stretch?

The Stretch offers a standard battery life of 8 hours, with an option to upgrade to a 16-hour battery life for longer operations.

3. How fast is the Boston Dynamics Stretch?

Stretch can move 800 heavy boxes per hour. Imagine how fit a person would need to be to move 800 boxes every hour and maintain the same pace for 8 hours straight.

Source: www.canva.com

Other Robotic Processes, Automation Tools, and Technology

Of course, Stretch is not the only robotic technology that is contributing to warehouse automation and streamlining logistics processes. What other automation technologies are available?

Fetch Robotics’ Autonomous Mobile Robots (AMRs)

Fetch Robotics offers AMRs that automate material transport within warehouses. Their robots can navigate autonomously through storage areas, retrieve items, and move them to designated locations, increasing operational efficiency.

They offer various types of robots designed for different kinds of goods. For example:

- Freight500 is suitable for handling smaller palletized loads and goods, with a capacity of up to 500 kg (1,100 pounds).

- CarConnect is designed for transporting carts, which are used for moving goods within the warehouse.

- RollerTop autonomously moves through the warehouse and transfers material.

- TagSurveyor automates inventory counting, allowing for more frequent stock checks and helping to prevent stock shortages.

River Systems’ Chuck

Chuck is an autonomous mobile robot, which essentially acts as your assistant. It helps improve putaway, picking, sorting, and returns tasks. Chuck will efficiently guide you through the warehouse, minimizing your steps. Additionally, it will carry all of the goods for you (up to 90.7 kg/200 lbs).

Source: www.canva.com

Proteus by Amazon

Proteus’s robotic systems are used in Amazon’s fulfillment centers to automate the movement of inventory. The robots bring shelves of items directly to human workers for picking, eliminating the need for workers to walk around the warehouse.

Just to clarify, Proteus robots are part of a much larger robotics network that Amazon uses to manage high-volume order fulfillment. Over 750,000 robots are currently deployed globally in Amazon warehouses. What other warehouse automation technologies make up the army of robots at Amazon?

- Sequoia: A robotic technology that stores and retrieves picking items for customers.

- Hercules: This system transports containers of items to employees who are selecting products for customer orders.

- Titan: This system transports large and bulky items to employees.

- Sparrow: A robotic arm technology that picks up and moves individual items from containers into specific totes, which are then sent to employees before the items are packaged.

- Packaging Automation: This is a machine that creates made-to-fit paper bags designed to match the dimensions of an order. This solution ensures that no more material than necessary is used for packaging orders.

- Robin: A robotic arm that lifts, elevates, and stores packages efficiently. It helps optimize the organization of goods before they are sent to the outbound dock for shipping or further processing.

- Cardinal: Just like Robin, Cardinal is a robotic arm that uses advanced AI and computer vision. Its task is to lift packages and place them into carts.

Source: www.canva.com

Tip: Did you know that warehouse automation can lead to a 25% increase in productivity, a 20% gain in space usage, and a 30% improvement in stock use efficiency? Read more about the benefits that robotic automation brings to warehousing.

Streamline your logistics processes

Are you looking for ways to streamline your logistics processes but currently have no plans to invest in automation and the newest robotic technologies? We have a solution that will also save you time and money, but at a fraction of the cost compared to warehouse automation. EasyCargo—a load planning software with a user-friendly interface that allows you to quickly and easily create load plans.